|

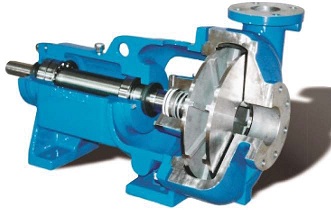

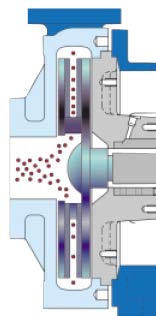

SpecificationsStandard: GB/T5656-2008Capacity: 5 ~ 1500m³/h Head: up to 250m Pressure: up to 50 bar Temperature: -30°C to +420°C DescriptionIntegrating the both advantages of the simple structure of the centrifugal pump and the strong capacity of the positive displacement pump, ZAP pump use the friction force and the centrifugal force to transport the fluids. Hitherto, the principle of most pumps is all the same that the mechanical parts (i.e., gears, plungers, rotors, blades) impact the fluids to make the fluids movement.For high viscosity fluids, high abrasion fluids, high-solids and/or gas-entrained fluids and shear sensitive fluids, the impact force is dangerous, which will bring pulsation, wear, piping damage. The ZAP pump can utmost solve all this problem and more reliable, more efficient, more costly, longer life cycle and less maintenance. The unique non-impingement technology ensures the bubbles in gas-entrained fluids will not burst in pumping. Moreover, there is no radial and axial force so that the pump needs less part replacement and repair. The ZAP pump is the best choice under fluids, ApplicationsThe ZAP pump is suitable for pumping high viscosity fluids, high abrasion fluids, high-solids and/or gas-entrained fluids and shear sensitive fluids. Using the unique technology, a 'non-impingement' impeller, ZAP is no-breaking the shear sensitive fluids to protect the pump and minimize the effects of pump performance, such as blockage, cavitation, minimal wear and handling shear sensitive fluids. |